// Product

storage

storage is the market leader in cheese cellar logistics. The cheese ripening process is digitally recorded, clearly displayed and seamlessly documented. In addition, the complete care management in the ripening cellar is organized with storage.

- Optimal management of the cheese maturing process

- Simple and intuitive monitoring of warehouse activities

- Clear, digitized and traceability of all data at any time

- Location-independent monitoring through connection with IIoT platform

// More quality in the ripening process – less effort

storage enables precise stock management and optimal management of the cheese-making process.

The internationally proven cheese cellar logistics

With storage, the complete cheese ripening process is digitally recorded and the cheese batches are clearly displayed. Thanks to intelligent software and networked hardware, storage guarantees seamless documentation of all process steps – from cheese storage to cheese removal and shipping.

Automatic care management in the cheese maturing cellar

Thanks to its modular design, storage can also be quickly and easily integrated into an existing cheese aging cellar. Numerous interfaces offer the possibility to integrate the system vertically and horizontally. As a result, storage covers not only pure storage management but also complete care management in the ripening cellar. With storage, you can easily carry out maintenance orders based on generally applicable rules or complex maintenance orders per batch.

Warehouse management software in the cheese warehouse for more quality in the ripening process

storage is specially designed, optimized and laid out for the workflows in cheese ripening centers. Thanks to the permanent, automated inventory of the storage status, all data such as the number of cheese wheels, cheese type, storage date, care data, quality and degree of ripeness of the cheese in the ripening cellar can be viewed and accessed at the push of a button.

With complete recording and documentation by storage, fast handling and processing of certification audits is guaranteed. Customer-specific reports can be easily implemented. With storage, processes, standards and legal requirements in the cheese ripening process are adhered to.

Maintenance recipes based on cheese age, cheese type, production company, etc. can be entered easily on the PC.

// Functions

Overview of the Available Features

Master data entry and management

For optimal storage and care of the cheese, all necessary data can be easily defined and entered in advance with storage. With the help of this data, storage is able to generate delivery bills and invoices in an uncomplicated way.

Master data entry and management

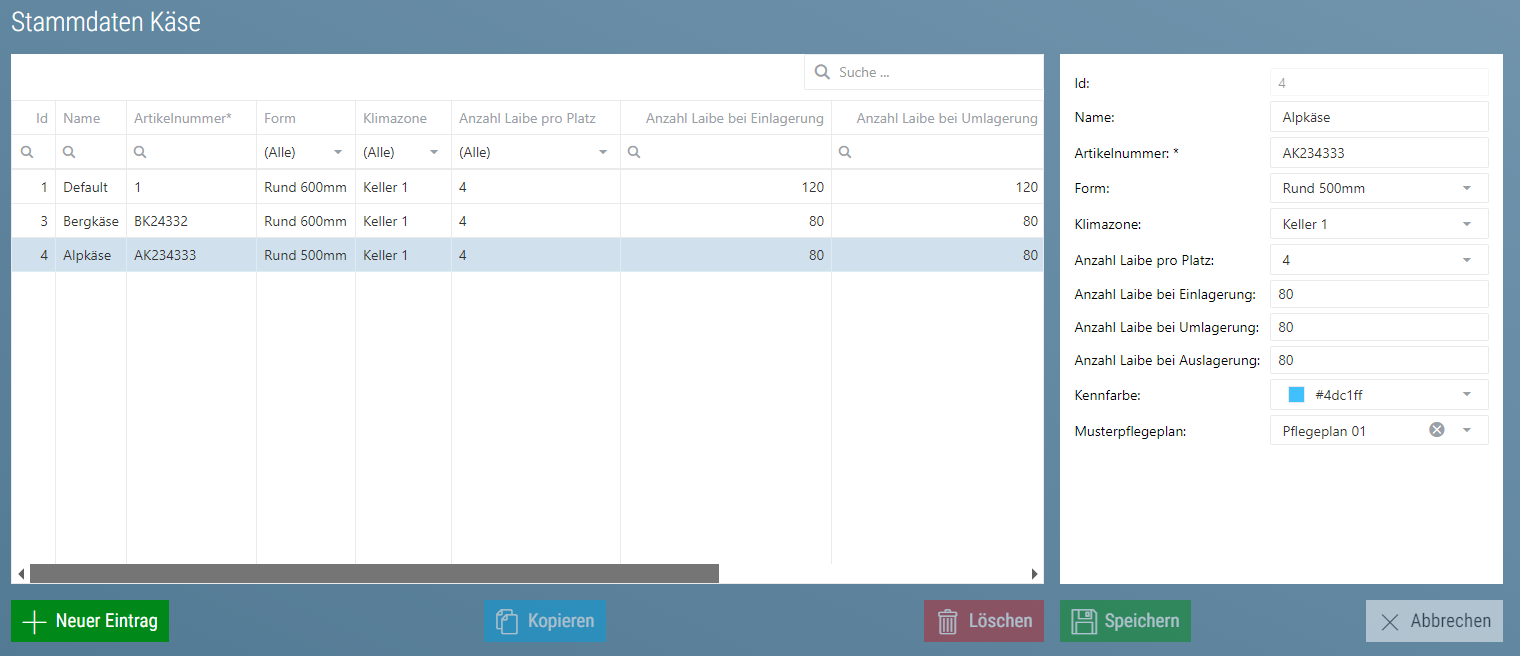

Cheese

The cheese master data defines the different types of cheese that storage can manage. Depending on the type of cheese, other care measures and other presets can be defined.

Addresses

storage is able to generate delivery bills and invoices based on warehouse data. For this purpose, a wide variety of addresses can be defined in the address master data for suppliers, manufacturers, carriers and buyers. The columns can be expanded very easily if necessary.

Cheese additive

Control functions in the warehouse process

The control functions in the storage process include all the necessary functions for automatically moving cheese into and out of storage.

Control functions in the warehouse process

Batch preperation

Storage prepares batches for storage by entering various information. Depending on the configuration, different parameters can be entered, such as delivery date, supplier, cheese, climate zone, MHD, care plan, etc. Once the batches have been prepared, the selected batches can be transferred for storage and the necessary free spaces can be searched for.

There is an optional possibility to automate the batch preparation.

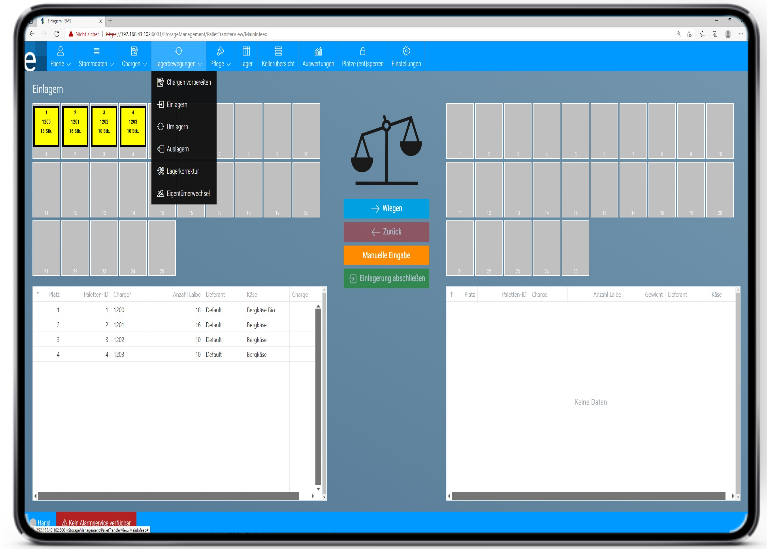

Putaway

With the putaway function of storage, a putaway weight can be assigned to the batches. The weight can be entered manually or automatically via a connected scale.

Putaway with a robot (optional)

The storage process can also be optionally automated by means of a connected robot. For this purpose, different tools are set on the robot and in the storage program.

If all data match (robot position, cheese format), a robot order is created in the software for this pallet. When all boards of the pallet are reported back as successfully stored by the robot, the storage for this pallet is automatically completed.

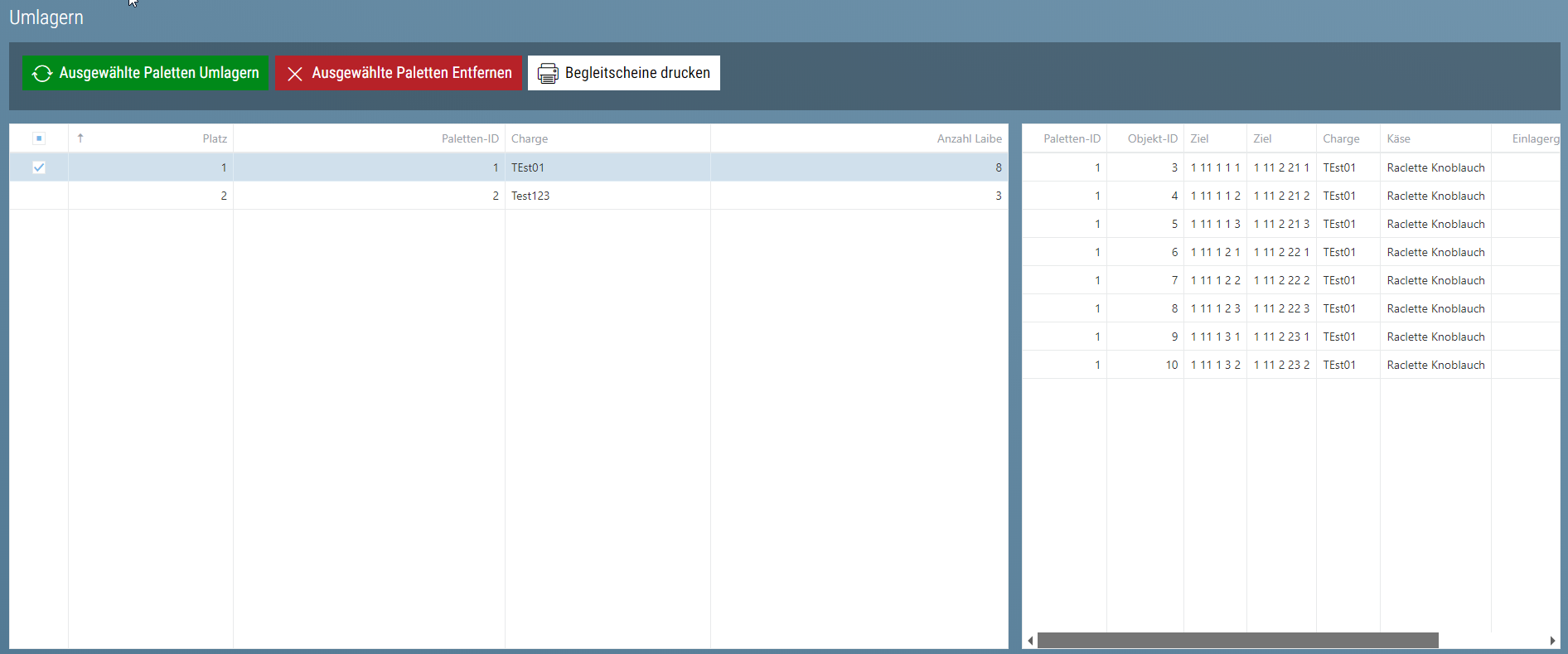

Transfer

With this function, all transfer pallets are clearly displayed. Here, too, transfering with a robot is possible.

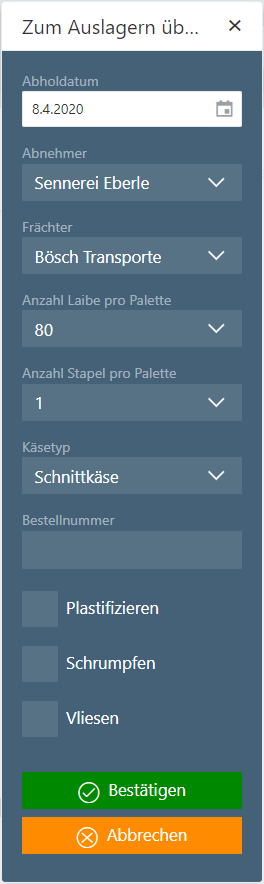

Retrieval

With the retrieval function of storage, a retrieval weight can be assigned to the loaves to be retrieved. The process works in the same way as the storage process. Here, too, the retrieval can optionally be carried out by means of a robot.

Other functions in the warehouse management process

storage optionally creates clear storage slips, storage lists, stock transfer slips, stock removal lists, stock removal slips, packing slips and stock removal reports.

Stock and stock promotions

With storage, all the contents of the warehouse are displayed completely and clearly. In addition, various actions can be easily performed in the cheese warehouse.

Stock and stock promotions

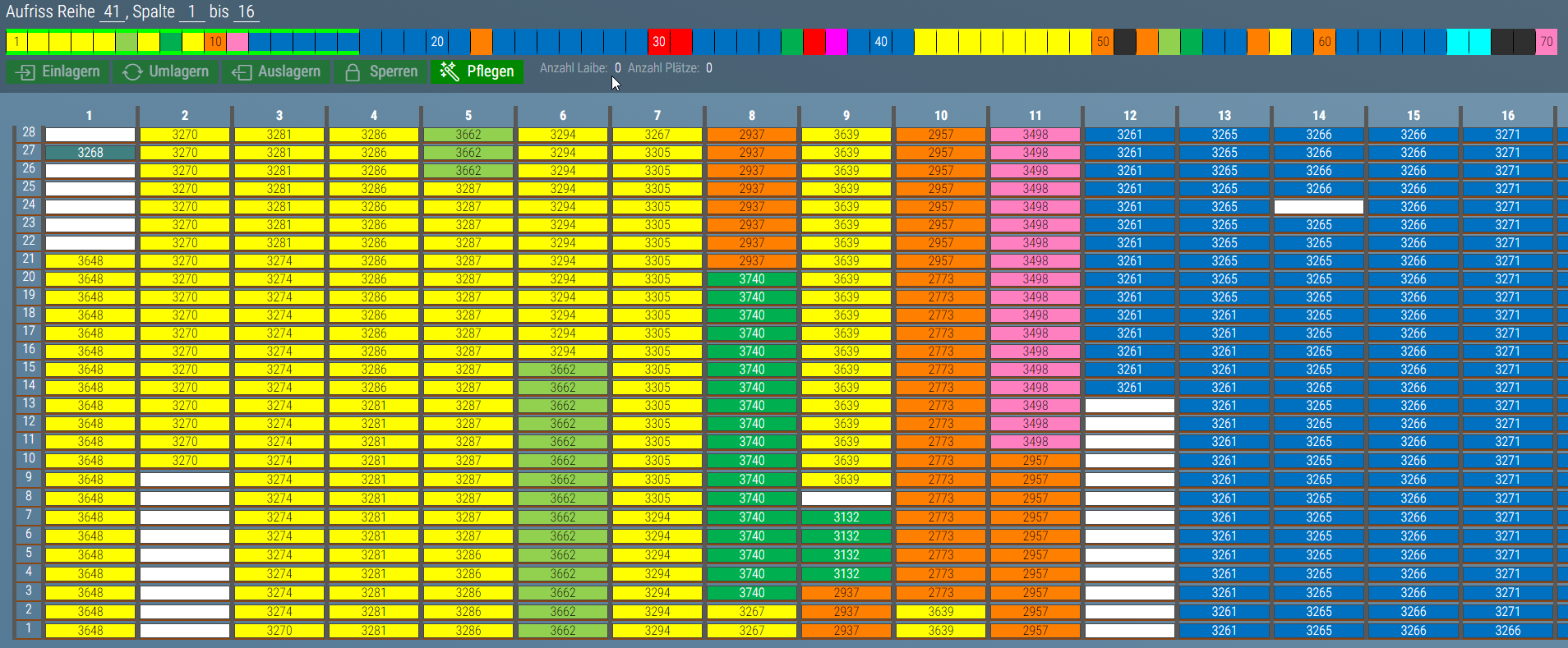

Dynamic display of the current stock level

storage graphically displays the contents of the complete warehouse as a table in a tabular warehouse overview.

Perform actions

With this function of storage different actions can be started with the cheeses.

Retrieval

Various settings for the removal of the cheese, such as the collection date, recipient, carrier can be made.

Transfer

With storage, uncomplicated and simple entries can be made for the storage strategy, the storage target and the number of loaves per batch.

Cellar management

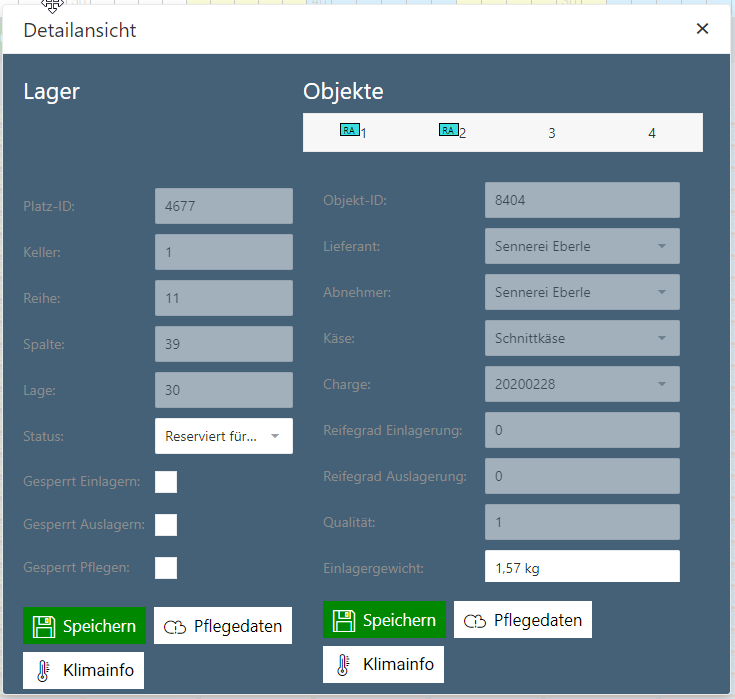

With the cellar management storage forms an overview of the complete ripening warehouse. With a graphically displayed row view and other tools from storage, cheese storage details are displayed.

Cellar management

Cellar overview

Based on the bars in each row, the row utilization of the warehouse can be seen. The total load is also displayed with storage.

Recording and monitoring of air conditioning data

With storage the course of temperature and humidity of the selected climate zone can be displayed. In addition, the minimum, maximum, average and median values for the selected period are displayed

Row view

The row view displays a row in the warehouse with the respective spaces. It is graphically displayed whether the seat is occupied or not.

Select and perform actions

Flexibly can be selected different places in the warehouse. Finally, with the selected loaves can be performed various actions.

Care details

The maintenance details show the maintenance history of the selected place or loaf. It can be seen when which robot has maintained the place/cheese with which maintenance program. If there was an error, the entry is highlighted and the corresponding message is displayed.

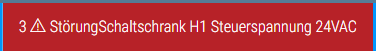

Notification and Alerts

All faults in the cheese maturing cellar system are detected by storage and displayed as alarms.

Notification and Alerts

Alarms

storage detects all capacitance limits/load limits, nursing robot malfunctions, air conditioning malfunctions, robot control malfunctions and sends an alarm.

Alarm archiving

Storage shows how many alarms are active in total and the alarm text of the last occurred alarm is displayed. All alarms are archived and are displayed in an alarm overview.

Maintenance programs and recipe management

If robots are used in the cheese ripening cellar, storage can be used to automate cheese care. Nursing recipes can thus be entered in an uncomplicated manner and nursing traceability is provided by storage.

Maintenance programs and recipe management

Robot orders

With storage all orders are listed, which the robot is to process. In addition, new car orders can be generated easily. Different settings for the new orders are easily possible.

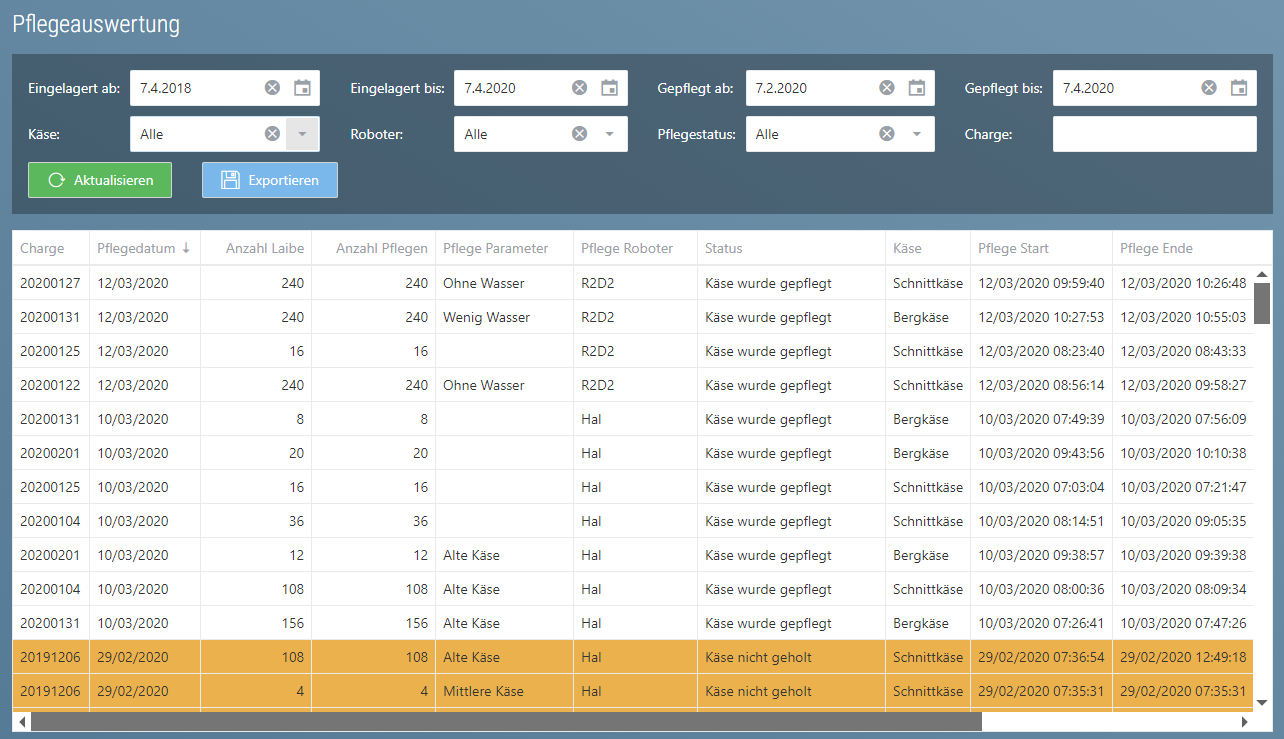

Care suggestions

storage displays the batches to be maintained based on the care plans or care parameter age assignments. The proposals are displayed by cellar. In addition, each individual row can be selected or deselected.

Care evaluation

Storage is used to display past maintenance.

Care parameters

Storage can be used to create care parameters that determine how the robot performs care.

Assign care parameters (optional)

With storage, the care parameters are linked to various conditions or rules. These conditions then result in the care proposals or the orders are generated.

Care plans and sample care plans (optional)

With a care plan from storage, the sequence of cares for a batch is defined. Each batch is assigned a care plan when it is placed into storage.

So that a new care plan does not have to be generated for each batch, there are also so-called sample care plans.. For this purpose, the sample care plan selected during storage is copied.

// References

Our Customers’ Opinion

Through the storage management software, we achieve a very high level of automation of the cheese ripening process. Storage organizes, plans and orchestrates the complete cheese ripening process from storage, through cheese care, to removal from storage. This ensures that storage is able to provide us with complete information about cheese care and our cheese stock at all times.

Digifai’s storage management software enables continuous, end-to-end monitoring and control of storage levels in the ripening cellar. Automation in the cheese warehouse means that all processes are monitored end-to-end and data is collected, providing interesting insights and safer planning for the future. With complete recording and documentation by storage, fast handling and processing of certification audits is guaranteed.

We chose storage to optimize our cheese cellar logistics. The software is easy to use and enables us to record the cheese ripening process digitally and across all locations. With storage we can create customized reports and have an overview of our cheese batches at any time. We are very satisfied with the solution and are happy to recommend it to others.

storage supports me in managing the ripening process of our high quality produced mountain cheeses in the Bregenzerwald cheese cellar. With the help of automatic documentation, the storage process is traceable at all times and rigorously minimizes administrative effort .

// Request Demo

Try storage now!

// Contact

Curious?

Do you have a concrete project in mind or would you like advice on whether you can benefit from digifai? I look forward to your message.

Michael Eberle

Chief Technology Officer

+43 5572 55580 803

michael.eberle@digifai.com

English

English Deutsch

Deutsch