// winwin with twin

The leading all-round simulation software for machines and robots

Safe, efficient and cost-saving from idea to operation with twin.

// More Quality & Efficiency – Less Risk

Less risk and lower costs, greater efficiency and reliability – a real win-win situation. Simple and secure from concept to operation with the digital twin from twin.

// References

Top companies develop with twin

// In Sales

Start with digital feasibility studies

Mit twin simulieren Sie bereits in der Angebotsphase realistische Abläufe und Szenarien. Begeistern Sie Ihre Kunden und beschleunigen Sie Entscheidungsprozesse.

Simple creation of sequences

Create processes with drag-and-drop ease and without programming knowledge. By creating even complex processes with ease, you can identify design flaws and bottlenecks early on. This allows you to optimise your processes in no time at all.

Fast model creation thanks to library

Benefit from existing models and create your digital twin in a matter of seconds. Whether robots or your individual standards such as grippers or entire machine modules – with twin you can quickly integrate existing components and start your simulation in no time at all. Maximum flexibility, minimum effort – for faster results and more efficient workflows.

Real robot kinematics

In your concept simulations, you can use robots effortlessly and optimize processes in no time. Create and optimize robot sequences with ease, directly in the simulation. Thanks to realistic speeds and accelerations, you can simulate movements precisely — for accurate cycle time estimates and optimal processes.

// In Engineering

Commission machines virtually

Put your machines into operation virtually before the real implementation begins. Accelerate the development process and avoid costly mistakes.

Test your real control program

Test your real control program, robot program, and HMI directly on the digital twin. Find and fix errors in your code before they cause real damage. Connecting a wide variety of controllers to twin has never been easier, even with thousands of IO signals.

Test and optimise mechanics

Check the functionality of your mechanical designs and optimize mechanical components directly in the simulation. twin’s state-of-the-art physics simulation realistically depicts forces and movements. This allows you to test and optimize even complex mechanical relationships.

Real-time collision detection

Identify and fix mechanical and software errors before real damage occurs. Save time and money through precise simulations and early problem detection.

// In Operation

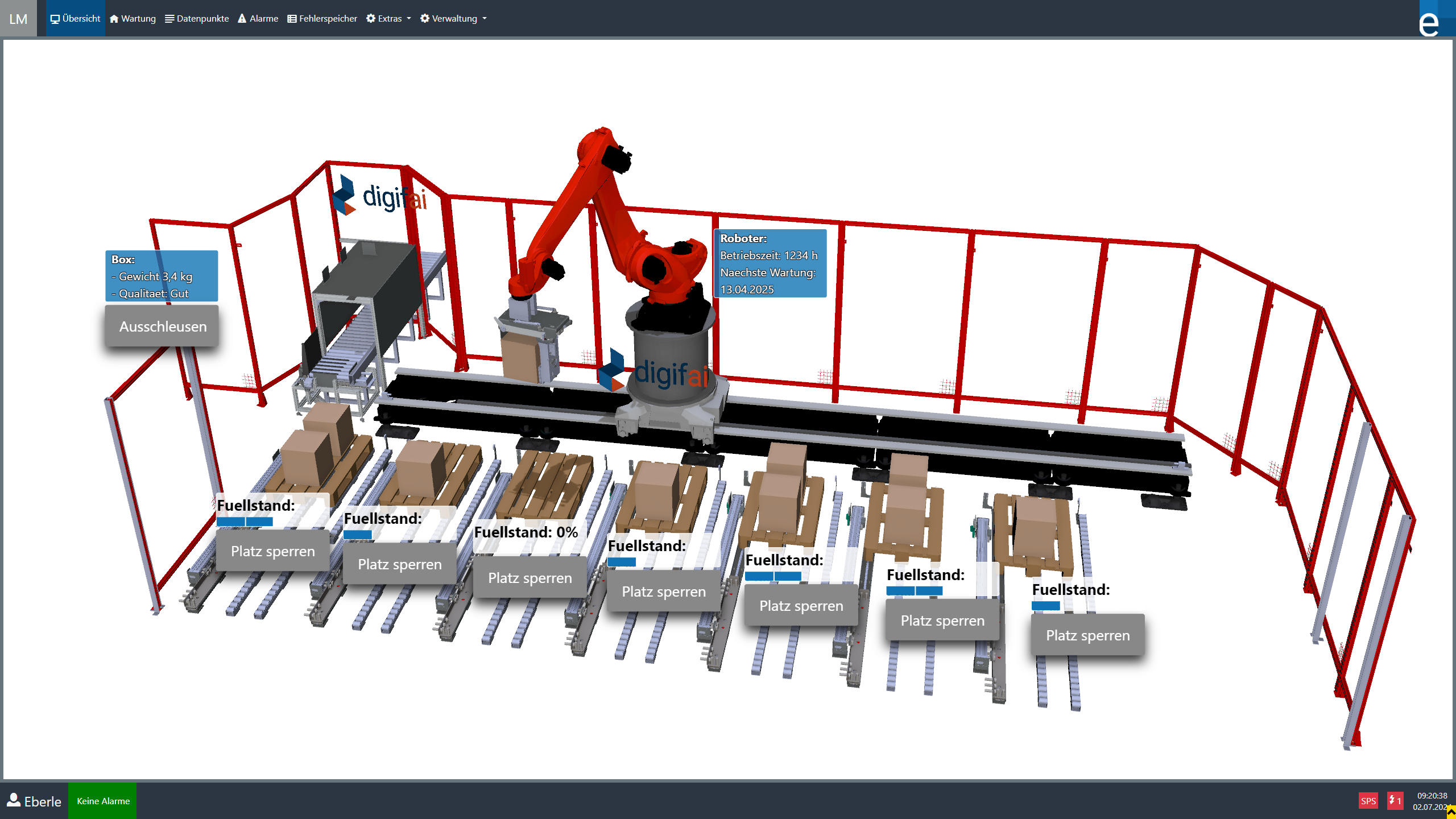

Intuitive 3D-HMI

Use modern 3D HMIs that are not only intuitive but also impressively designed to increase user-friendliness on the machine.

Seamless integration into existing HMIs

twin integrates seamlessly into existing HMI systems — regardless of the provider or architecture. This allows you to use your familiar and proven environments and enhance them with the advantages of 3D operation.

Reuse models without additional effort

Save time and money by seamlessly reusing the models created in engineering in your HMIs. Added value without added effort.

Improved user experience for plant operators

Offer plant operators a new user experience. This simplifies operation, reduces training costs, and minimizes downtime. For example, display fault messages where they occur and guide plant operators through maintenance scenarios. Or enable natural operation, where operators can tap machine components directly in 3D to open manual modes.

// References

Our Customers’ Opinion

The simulation software twin delivers what digifai promises. We are thrilled.

The software fulfils all our wishes – we can master even the most demanding requirements with twin. Such fast and competent support is unique. twin is constantly evolving and always focusses on customer needs. Keep up the good work!

We are an Austrian SME, develop turnkey special machines and have been looking for a suitable software for the virtual commissioning of our machines for a long time. With the software twin from digifai, we now secure the complete development process of our machines at an early stage and save valuable time during commissioning! With twin, we have definitely backed the right horse in this area!

twin offers us as a medium-sized special machine manufacturer the possibility to minimize risks in the concept phase, to secure the design at an early stage and with the virtual commissioning a shorter time-to-market for our customers.

The possibility of simulating designs physically correctly, checking them for feasibility with various use cases and putting them into operation virtually opens up a completely new market access for us as a service provider in partnership with digifai.

By simulating the entire machine at an early stage, we can significantly reduce risk and save costs. The entire control software including HMI and control system is ready and tested before the machine is built.

To conduct our research, we need a secure environment in which we can test AI algorithms for machines as realistically as possible. twin is perfectly suited for this purpose.

twin enables us to create digital twins of our production machines. digifai’s many years of experience as an integration partner is visible in the small but important details of their solutions.

// Therefore twin

Overview of the Available Features

By practitioners for practitioners: You will be amazed at how quickly you will find your way around the software.

You do not need a CAD program to work with twin. Easily import the most popular CAD formats.

Add sensors and actuators from an extensive library to your simulation.

Easily create sequences and behaviours with sequences and scripts.

Teach robot movements with the integrated robot controller.

Simple connection of controllers and robots even with thousands of signals.

Achieve unprecedented realism with state-of-the-art physics simulation. And all this with minimal configuration effort.

Extend twin’s functionality to meet your needs.

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est

// Further information about twin

Everything you need in one place

Whitepaper “Digital Twins in the Equipment Lifecycle”

A white paper on the use of digital twins in the plant lifecycle (PDF file)

// Further information about twin

FAQ’s

What sector is twin suitable for?

twin is a powerful, all-round simulation software that is used in almost every industry. Whether in the automotive, food, wood processing, plastics, intralogistics, or pharmaceutical industries, twin offers flexible solutions for specific requirements. Benefit from software that allows you to optimize your processes across all industries.

Is twin suitable for special machines or standard machines?

With twin, you are well equipped – regardless of whether you develop special or series machines. Our software reduces risks in your mechanical engineering and automation projects and enables fast and reliable results thanks to its intuitive operation.

Is there a free trial version?

Yes! You can request a free trial version of twin. This time-limited full version gives you the opportunity to test the entire range of our software without obligation – experience the advantages of twin for yourself.

How do I learn to use twin?

Getting started with twin is child’s play: the software is clearly structured and intuitive to use. You also benefit from a comprehensive range of training courses that prepare you optimally for use – so you can exploit the full potential of twin right from the start.

Do I need a special computer to work with twin?

twin runs on all current computers and laptops. For optimal performance with particularly large or complex projects, we recommend a powerful system with a dedicated graphics card. This will ensure that your simulations run smoothly.

What licence models are available?

With twin, you have maximum flexibility when it comes to licensing:

- Purchase or rent: Decide for yourself whether you want to buy twin permanently or rent it flexibly.

- Individual license types: Choose between a per-user license, a per-computer license, or a network license for maximum flexibility within your team.

No matter what your requirements are, we offer a tailor-made solution that fits your business perfectly. Contact us and we will help you find the ideal licensing option.

How can I by twin?

Ready to get started with twin? Contact us directly by email — our team looks forward to working with you to find the best solution for your needs.

How often is the software updated?

We listen to our customers! That’s why we release a new version of twin every two months, taking your wishes and requirements into account. These regular updates keep you up to date at all times – for maximum efficiency and innovation.

What can I do if I get stuck with a problem?

Our support team is always there for you! Simply contact us by

email or phone, and one of our experts will provide you with fast and competent assistance. With twin, you are never on your own.Can I extend the software's functionality?

Yes, twin has a modular structure and can be expanded as required. With our Software Development Kit (SDK), you can develop your own modules — in C#, for example. This allows you to tailor twin perfectly to your individual requirements.

// Contact

Curious?

Do you have a concrete project in mind or would you like advice on whether you can benefit from digifai? I look forward to your message.

Michael Eberle

Head of digifai

+43 5572 55580 803

michael.eberle@digifai.com

English

English Deutsch

Deutsch